No.1 Textile Industry HVAC Specialist in Bangladesh

What is Textile Industry Air Conditioning?

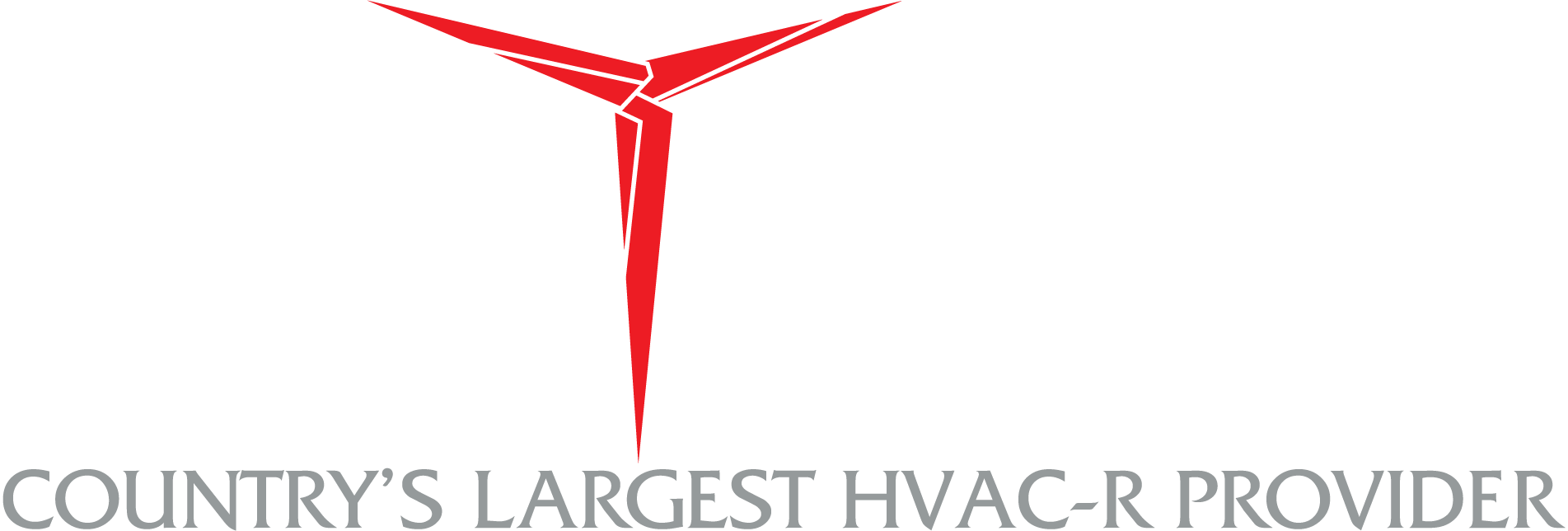

Textile factory HVAC system or Air conditioning in the textile industry consists of continuous control of indoor air temperature, humidity, air movement, dispersion, and ventilation within an enclosed textile production space. Controlling dust & debris along with suppressing heat generated from machine operation also falls under the criteria of Textile Industry Air Conditioning.

Necessities of Air Conditioning in textile mills for Humidity Control

Air Conditioning in textile mills is responsible for controlling the production environment in all aspects. Especially in specific production lines like spinning, and weaving. Textile industry HVAC system plays a crucial part in ensuring equipment longevity, controlling optimal environment, maintaining production quality standards, and ensuring human comfort. Without an efficient air conditioning system, the existence of these individual criteria fails to create a healthy environment and leads to production disruption.

- Humidity Control (Too Dry Air Solution): Imbalance air humidity in a textile mill disrupts yarn quality by making it too harsh or too soft. Yarn in less humid conditions becomes too thinner, more fragile, and easier to tear apart. Due to too dry air, yarn also tends to generate static electricity within itself making the production process difficult. Often the static electricity within yarn can cause equipment malfunction leading to costly unplanned downtime. Proper air conditioning maintaining required relative humidity level preserves yarn quality making it suitable for production & manufacturing.

- Humidity Control (Too Humid Air Solution): In high-humidity conditions, natural fibers like cotton and wool absorb excessive moisture as they are highly hygroscopic. Leading to swelling and changes in their physical properties. High humidity causes textiles to expand or stretch by gaining and losing moisture in each stage of production. This can lead to issues with the sizing and fitting of garments or the proper dimensions of final products. It can be especially problematic in industries where precision and consistency are essential. Excessive moisture in the air can create conditions conducive to mold and mildew growth on textiles. With optimal air conditioning facilities with precise humidity & temperature control, textile manufacturing facilities can reach the next level of efficient production at a minimum cost expenditure.

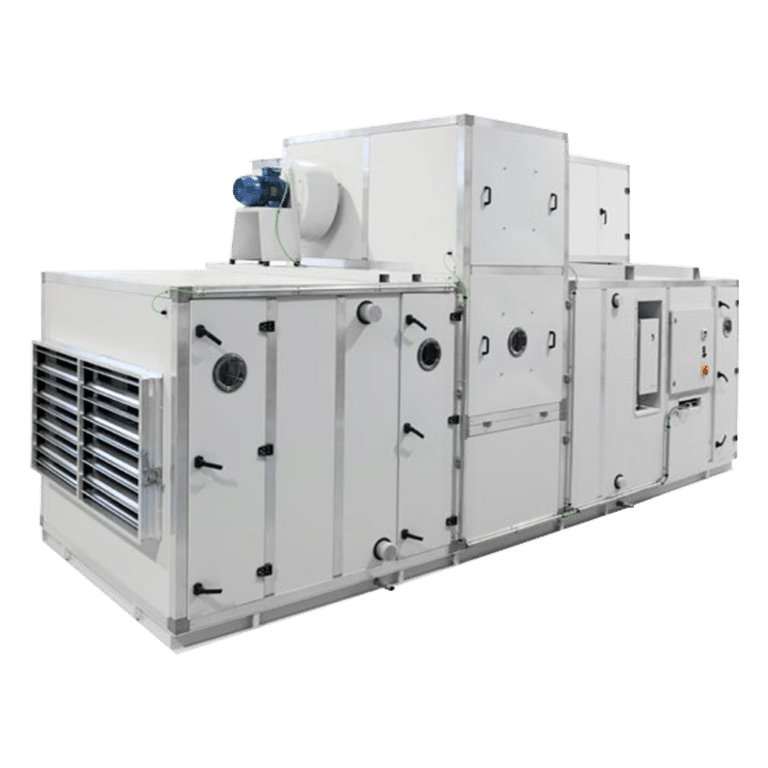

Industrial Dehumidifiers To Control Humidity Precisely

Fisair DFLEX Series Dehumidifier

Fisair DFRA Series Dehumidifier

Fisair DFRB Series Dehumidifier

Fisair DFRC Series Dehumidifier

Importance of HVAC in textile facility for Machinery Protection

Textile manufacturing facilities are full of expensive machinery like a Jacquard machine or a spinning machine. Producing loom of yarn to finished products like sweaters, socks, sweatshirts or trousers continuously creates dust and debris within the production facility. Expensive machinery like Jacquard machines are susceptible to clogging due to excessive dust and that leads to reducing machinery lifetime while creating unwanted downtime in production. An optimized air conditioning facility with a proper ventilation system and dust control mechanism can keep your production house running non-stop by keeping the dust rate within the required level.

Efficient Chiller Solution To Protect Equipment Longevity

Save 50% Electricity Bill With SMARDT Air Cooled Oil Free Chiller

Get Highest ROI With SMARDT Magnetic Bearing Water Cooled Chiller

Role of HVAC in textile factory to Maintain Production Standards

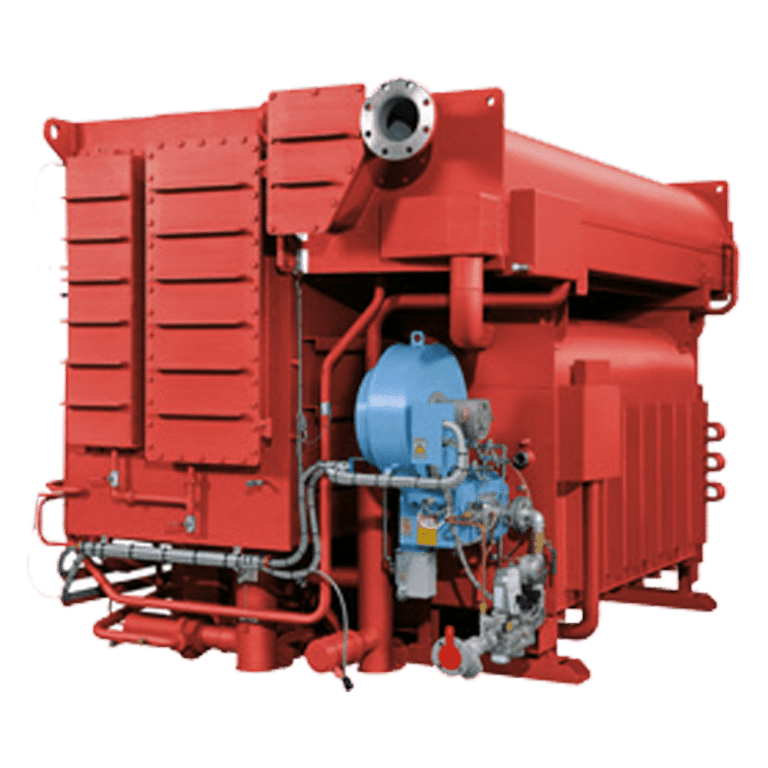

Besides using natural and azo-free dyes or using organic fibers, minimizing carbon footprint, and reducing energy usage while also creating healthier & comfortable workspaces are major environmental criteria for a garment manufacturing factory. In all of these aspects, an efficient & optimized air conditioning system can significantly help meet the required environmental criteria. For example, the efficient and carbon footprint reduction-capable Kawasaki Absorption Chiller has been reshaping the power production cycle of textile manufacturing facilities. These chillers generate up to 40% of free cooling energy from waste heat or water contributing to energy production and cost reduction significantly.

Green & Efficient Absorption Chiller Solution for Textile Industry

Kawasaki Steam Fired Absorption Chiller

Kawasaki Gene Link Absorption Chiller

Importance of HVAC in textile factory to Prevent Health Hazards

Human Comfort: Heat generated from the machinery on a production floor and dust generated from the weaving process create discomfort for the operator working in line. Modern dust control mechanisms lined with strategically positioned indoor air conditioning units create a comfortable environment for the men & women behind the machines. Without a strategically perfect air conditioning facility, productivity decreases in a manufacturing facility & reports say within a comfortable environment human productivity increases up to 10%. Thus, ensuring a comfortable environment using an efficient HVAC facility creates a productive environment for working personnel in a textile mill.

Benefits of Efficient HVAC in Textile Manufacturing Facility: (In Short)

Preserves yarn quality

Extends equipment longevity

Protects human health by preventing health hazards

Controls dust & debris

Reduces energy cost

Increases productivity

Saves operational cost

Avoids unplanned costly downtime

Textile Jacquard Factory HVAC Specialist in Bangladesh

An important segment of a Textile industry is the Jacquard Factory. With properly furnished products, Jacquard factories are contributing significantly to the ready-made export section of Bangladesh. Likewise, every sector of textile production, an efficient HVAC system is equally important in a Jacquard Factory. For over 20+ years, Tritech has been providing efficient air conditioning solutions to country’s most prestigious textile industries. Completing more than 200+ industrial HVAC-R projects, Tritech has established itself as the No.1 Jacquard Factory HVAC Specialist in Bangladesh.

Before delving into the intricate method of ensuring optimum environment in a Jacquard Factory using efficient air conditioning, let’s learn a few basics about a Jacquard Factory.

What is a Jacquard Factory?

A Jacquard factory is a type of textile manufacturing facility that specializes in the production of fabrics using Jacquard weaving techniques. Jacquard weaving process creates intricate and complex patterns to be woven into fabrics.

What are the final products of a Jacquard Factory?

Jacquard factories can produce a wide range of end products, including sweaters, socks, sweatshirts, trousers, and home textiles such as curtains and upholstery, tapestries, and specialty fabrics. The choice of pattern and fabric varies widely based on customer demands.

Who are the major Jacquard Product Manufacturers in Bangladesh?

You might be astonished to know that, in the 2022-2023 fiscal year, Bangladesh’s exports in the RMG sector surged by 10.7% than the previous fiscal year reaching to approximately $42 Billion. Consistent production standards, efficient factory working processes, and green technology adoption increased the demand for ready-made products generated in Bangladesh. Considering the production rate of ready-made garments manufactured in a single day, Bravo Apparels, MNR Sweaters Limited, Preetty Sweaters Ltd, and Irish Fashion House are the major jacquard product manufacturers in Bangladesh.

Factors related to Jacquard Factory Air Conditioning

In the intricate world of textile manufacturing using jacquard machines, every detail matters. Consistency is the hallmark of quality and Precise temperature control ensures each sweater meets the consistent highest quality standards.

Extreme temperatures in Jacquard factories can disrupt yarn tension, reduce equipment longevity & create health hazards for working personnel. Leading to disruption in required production standards. So, Today we’ll delve into the vital factors behind the necessity of maintaining optimal temperature and dust control in your Jacquard Factory.

- Preserve yarn quality: In the jacquard manufacturing industry, Yarn is the lifeblood of every sweater. Maintaining the correct temperature and humidity levels preserves its quality, safeguarding the integrity of your final product.

- Machinery clogging protection: Additionally, jacquard machines are susceptible to clogging from dust and debris. Neglecting dust control can result in operational issues, leading to costly downtime during production.

- Prevent health hazards: Excessive dust poses health hazards to factory workers, potentially causing respiratory problems and other health issues. A clean and controlled environment is also essential for their well-being.

- Energy Efficiency: An efficient HVAC system can help regulate temperature and humidity, saving energy costs in the long run.

- Consistent Production: Temperature and humidity fluctuations can lead to yarn breakage, machine malfunctions, and inconsistent production, affecting productivity and profitability.

An improper jacquard factory HVAC system can disrupt production, compromise product quality, pose health risks, and decrease the longevity of expensive machinery in a sweater factory using Jacquard machines. Maintaining a controlled environment is essential for both operational and safety reasons. Thus, a dust-free environment and precise temperature control at your Jacquard factory extend the lifespan of valuable assets while maintaining proper product integrity.