Textile Industry HVAC

- Home

- Textile Industry HVAC

Achieve Textile & Garment Industry Climate Excellence with Tritech’s Tailored HVAC Solutions

Welcome to Tritech, the premier HVAC provider for textile, garment, and washing factories. At Tritech, we understand the unique challenges and demands of the textile industry, and we are dedicated to delivering state-of-the-art HVAC solutions that optimize your production environment. Our advanced systems are designed to provide precise climate control, ensuring the highest quality fabric production, seamless garment manufacturing, and efficient washing processes.

Tritech has established itself as a leader in providing LEED-certified HVAC services to prominent factories such as Columbia Washing Plant Limited, MNR Sweaters Ltd, and numerous others. Our commitment to sustainability and energy efficiency ensures that these factories meet and exceed the stringent requirements of LEED certification. By implementing advanced HVAC technologies and practices, Tritech helps these facilities reduce their environmental impact, improve indoor air quality, and achieve significant energy savings.

Tritech’s innovative HVAC solutions are tailored to meet the specific needs of your facility, enhancing air quality, maintaining consistent temperature and humidity levels, and improving overall operational efficiency.

With highly skilled professionals and extensive industry experience, Tritech ensures that your HVAC systems are designed, installed, and maintained to the highest standards. Trust Tritech to deliver reliable, efficient, and comprehensive HVAC solutions that support your production goals, enhance product quality, and create a comfortable and safe working environment for your staff.

Get Energy Efficient Textile, Garment & Washing Factory HVAC Services for Increased Production Efficiency with Tritech

Why Choose Tritech For Garment, Textile & Washing Factory HVAC Services in Bangladesh?

#1 HVAC Specialist for Textile & Garment Industry

Tritech is Bangladesh’s foremost Textile & Garment Industry HVAC specialist, renowned for optimizing operations with unparalleled expertise. Trusted by prestigious brands like MNR sweaters, Pandora, Bravo Apparels, IRIS Fashions, and many more. Our extensive experience in this sector allows us to design and implement HVAC solutions that precisely meet the unique requirements of textile and garment manufacturing facilities.

Protect Product Integrity with Global Leading HVAC Products

Tritech ensures the protection of product integrity in the garment, textile, and washing industry by providing HVAC solutions that utilize global leading products. Our systems from top-tier manufacturers like Elta, Kruger, and Systemair are designed to maintain precise control over temperature and humidity levels, crucial for preserving the quality of textiles and garments during manufacturing and storage. By preventing fluctuations that could compromise fabric quality, color consistency, and overall product durability, Tritech helps manufacturers deliver superior products to their customers.

Proven Track Record in Textile & Garment Industry HVAC Implementation

Tritech has a proven track record of successfully implementing HVAC solutions in the textile and garment industry. Our extensive portfolio includes high-profile projects such as Columbia Washing Plant Limited and MNR Sweaters Ltd, showcasing our ability to meet the specific HVAC needs of these facilities. Our expertise ensures optimal environmental conditions that enhance operational efficiency, worker comfort, and product quality. This consistent delivery of reliable and efficient HVAC solutions has cemented Tritech’s reputation as a trusted partner in the textile and garment sector.

Expert in LEED Factory HVAC

Tritech is an expert in providing LEED-certified HVAC solutions for textile, garment, and washing factories. Our focus on sustainability and energy efficiency aligns with the stringent requirements of LEED certification, helping facilities achieve green building standards. By incorporating advanced HVAC technologies and eco-friendly practices, we not only reduce environmental impact but also improve indoor air quality and energy savings. Tritech’s successful LEED projects, such as those for Columbia Washing Plant Limited and other leading factories, demonstrate our capability to deliver HVAC solutions that support sustainable and responsible manufacturing practices.

Let Tritech be your trusted partner for creating a Healthy, Efficient, and Sustainable Garment Factory Environment.

Get The Best Garment, Textile & Washing Factory HVAC Solutions with Tritech

Efficient Energy Recovery Ventilation System

Tritech’s Efficient Energy Recovery Ventilation (ERV) systems are designed to significantly reduce energy consumption while maintaining optimal indoor air quality in garment, textile, and manufacturing facilities. By capturing and reusing the energy from exhaust air, our ERV systems minimize the need for additional heating or cooling, leading to substantial energy savings. This is particularly important in facilities with high ventilation requirements, where maintaining a comfortable and healthy environment is crucial for both product quality and worker well-being. Tritech’s ERV solutions ensure that fresh air is continuously circulated without sacrificing energy efficiency, making them an ideal choice for energy-conscious industrial operations.

SMARDT Oil-Free Chillers for Ultimate Efficient

Tritech offers SMARDT oil-free chillers, which are renowned for their exceptional efficiency and reliability. These chillers use magnetic bearing technology, eliminating the need for oil, and thereby reducing maintenance costs and enhancing operational efficiency. In the demanding environments of garment, textile, and manufacturing facilities, maintaining precise temperature control is critical. SMARDT chillers deliver unparalleled performance with low energy consumption, making them an excellent choice for facilities looking to optimize their cooling processes while minimizing their environmental impact. As the sole distributor of SMARDT chillers in Bangladesh, Tritech ensures that clients receive the best in cutting-edge cooling technology.

Suggested Most Efficient Oil Free Chiller Products for Garment and Textile Industry

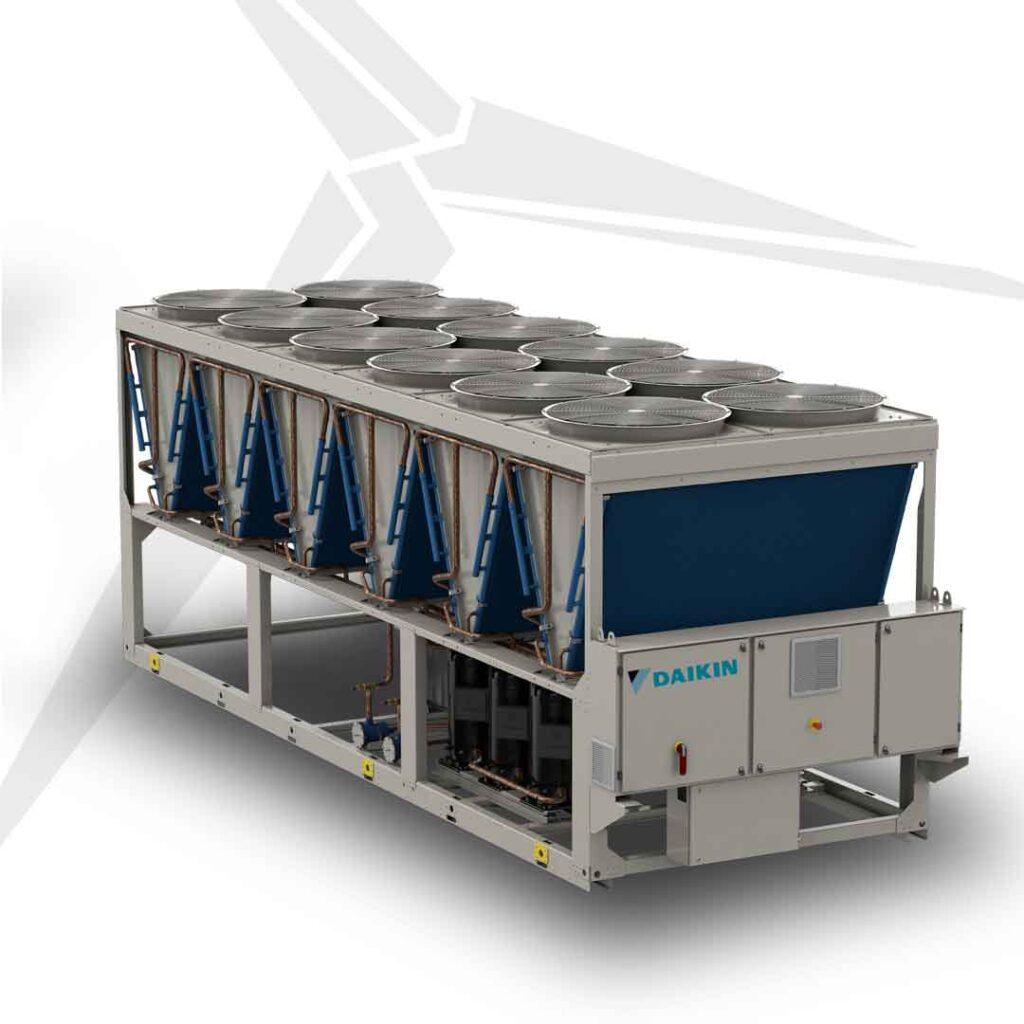

Global Leading Electric Chillers for Reliable Operation

Tritech’s global leading electric chillers provide reliable and efficient cooling solutions tailored to the needs of garment, textile, and manufacturing facilities. These chillers, sourced from top-tier manufacturers, offer robust performance and are capable of maintaining consistent temperatures under varying load conditions. Reliability is paramount in industrial settings, where even minor disruptions can lead to significant production losses. Tritech’s electric chillers are engineered for durability and efficiency, ensuring that operations run smoothly and continuously. By integrating these chillers, facilities can achieve superior cooling performance while benefiting from reduced energy costs and improved system reliability.

Suggested Most Efficient Chiller Products for Your Textile, Garment or Washing Factory Project

Kawasaki Absorption Chiller for Free Cooling of 40%

Tritech’s Kawasaki absorption chillers offer an innovative and sustainable cooling solution, providing up to 40% free cooling. These chillers utilize waste heat from industrial processes, converting it into useful cooling without relying heavily on electricity. This not only reduces the operational costs but also significantly lowers the carbon footprint of the facility. In garment, textile, and manufacturing settings, where energy consumption is a major concern, Kawasaki absorption chillers provide an eco-friendly alternative that aligns with green building initiatives. As the exclusive provider of Kawasaki chillers in Bangladesh, Tritech ensures that clients have access to one of the most efficient and environmentally responsible cooling technologies available.

Suggested Most Efficient Absorption Chiller from Kawasaki for Garment and Textile Industry

The Best in Class Dehumidifier From Global Leading Brands

Dehumidifiers ensure that all stages of production, from raw material handling to final product storage, maintain consistent environmental conditions, leading to uniform product quality. By controlling humidity, dehumidifiers reduce the risk of defects such as mold growth, color inconsistencies, and material degradation, which can occur due to excess moisture. Maintaining optimal humidity levels enhances the efficiency of machinery and processes, reducing downtime and increasing overall productivity. Controlling humidity helps prevent the growth of mold and mildew, which can cause respiratory issues and other health problems for workers. Excessive humidity can cause corrosion and other damage to machinery and equipment. Dehumidifiers help protect these investments by maintaining a dry environment. By preventing moisture-related issues, dehumidifiers reduce the need for frequent maintenance and repairs, leading to cost savings.

Suggested Most Efficient Dehumidifier Solution for Textile or Garment Factory

Global Leading Brand Collaboration